Semiconductor and Electronics

Chemical Mechanical Planarization Market

Chemical Mechanical Planarization (CMP) Market Size, Share, Growth & Industry Analysis, By Type (Equipment and Consumables), By Application (Compound Semiconductors, Integrated Circuits, MEMS and NEMS, and Others), and Regional Analysis, 2024-2031

Pages : 120

Base Year : 2023

Release : July 2024

Report ID: KR901

Chemical Mechanical Planarization Market Size

The global Chemical Mechanical Planarization (CMP) Market size was valued at USD 6,230.1 million in 2023 and is projected to grow from USD 6,579.5 million in 2024 to USD 10,101.7 million by 2031, exhibiting a CAGR of 6.32% during the forecast period. In the scope of work, the report includes solutions offered by companies such as Air Products Inc., Applied Materials, Inc., Cabot Corporation, EBARA Technologies, Inc., Fujimi Corporation, Hitachi Chemical Co., Ltd., Lapmaster Wolters GmbH, Okamoto Machine Tool Works,Ltd., The Dow Chemical Company, LAM RESEARCH CORPORATION, and others.

The expansion of the market is driven by the rapid growth of the semiconductor industry. This fuels demand for CMP, as it is essential for achieving the high level of surface planarity required in semiconductor manufacturing. Technological advancements in electronic devices, such as smartphones and tablets, further contribute to market growth.

Additionally, the increasing adoption of CMP in the production of memory devices, including DRAM and NAND flash, boosts market development. Environmental regulations that promote the use of eco-friendly CMP slurries and pads further propel market expansion. Moreover, the continuous need for miniaturization in electronics and the development of innovative CMP solutions play a significant role in boosting market development.

The Chemical mechanical planarization market is experiencing steady growth, propelled by ongoing advancements in semiconductor technology and increasing demand for high-performance electronic devices. CMP is a critical process in semiconductor manufacturing, which ensures the flatness and smoothness of wafer surfaces. This technique combines chemical and mechanical processes to remove material and planarize surfaces, enhancing the performance and reliability of electronic components.

The market is characterized by the presence of several key players, ongoing research and development activities, and a focus on improving process efficiency and reducing environmental impact. The Asia-Pacific region, particularly China and Taiwan, dominates the market due to their extensive semiconductor manufacturing capabilities.

Chemical mechanical planarization (CMP) is a semiconductor fabrication process that combines chemical and mechanical forces to achieve surface planarity on wafers. It involves the use of a CMP slurry, which contains abrasive particles and reactive chemicals, and a polishing pad to remove excess material and flatten the wafer surface.

CMP is essential for the production of integrated circuits, enabling the creation of multiple layers of wiring with precise alignment. This process is crucial for achieving the high level of surface smoothness required for advanced semiconductor devices. CMP is widely used in the manufacturing of microprocessors, memory devices, and other semiconductor components, significantly advancing the miniaturization and enhancing the performance of electronic products.

Analyst’s Review

Manufacturers are actively focusing on innovation and product development to meet evolving industry demands. This includes the introduction of advanced CMP equipment and consumables that enhance process efficiency and productivity rates in semiconductor manufacturing. Companies are investing heavily in research to develop eco-friendly CMP solutions, thereby addressing environmental concerns while maintaining high-performance standards.

- In October 2023, SKhynix developed recyclable pads in order to match the performance of new pads in semiconductor production. They planned to introduce these pads to the Touch CMP process the following year, which was less complex with a lower error risk. This development aimed to reduce costs and environmental impacts from disposing of consumable materials such as wafers, slurries, and pads.

Manufacturers are recommended to continue investing in R&D for technological advancements and sustainable practices. Collaborations with semiconductor firms for tailored solutions and expanding market reach in emerging economies further present strategic opportunities for growth and competitiveness in the chemical mechanical planarization market.

Chemical Mechanical Planarization Market Growth Factors

The market is experiencing an increasing demand for advanced semiconductor devices. The rapid evolution of consumer electronics, such as smartphones, tablets, and wearable devices, is boosting the need for smaller, more efficient semiconductors. CMP plays a crucial role in achieving the necessary surface smoothness and planarity for these advanced components.

As semiconductor manufacturers strive to meet the growing demand for high-performance electronic devices, they are continuously investing in CMP technology. This investment includes developing new CMP slurries and pads, enhancing process control, and improving the overall efficiency of CMP operations. These initiatives are expected to propel the chemical mechanical planarization market growth.

- In June 2023, AMD unveiled its future computing roadmap, alongside a range of products and partnerships aimed at advancing data center innovation. Collaborating with industry giants such as AWS, Citadel, Hugging Face, Meta, Microsoft Azure, and PyTorch, AMD showcased its AI Platform strategy. This included the introduction of the AMD Instinct MI300 Series accelerator family, featuring the AMD Instinct MI300X accelerator, designed to cater to generative AI workloads. Additionally, AMD highlighted its ROCm software ecosystem, aimed at enhancing AI software compatibility and performance across AMD's accelerators.

The environmental impacts of the CMP process, particularly regarding the disposal of used slurries and pads, that contain hazardous chemicals, present a key challenge. Addressing this challenge requires the development of eco-friendly CMP materials and the implementation of efficient waste management practices. Manufacturers are increasingly focusing on creating biodegradable and less toxic CMP slurries that maintain performance while reducing environmental harm.

Additionally, recycling programs and waste minimization strategies are being implemented to manage and reduce the disposal of hazardous materials. By investing in sustainable practices and green technologies, market players are striving to overcome environmental challenges and ensure long-term growth.

Chemical Mechanical Planarization Market Trends

The market is experiencing a notable trend toward the adoption of advanced CMP technologies. Manufacturers are increasingly integrating novel materials and techniques to improve the precision and efficiency of the CMP process. These advancements include the development of new slurry formulations, enhanced polishing pads, and advanced metrology systems for real-time monitoring.

The use of artificial intelligence and machine learning in process optimization is becoming increasingly prevalent, enabling more precise control over the CMP process. This trend is further fueled by the need to produce smaller, more complex semiconductor devices with higher performance, as well as to reduce costs and improve yield rates in manufacturing.

There is a growing focus on environmental sustainability. As regulatory pressures and consumer demand for eco-friendly products increase, manufacturers are prioritizing the development of green CMP solutions. This includes the creation of biodegradable slurries and the use of recyclable polishing pads. Additionally, companies are implementing closed-loop systems to reduce water and slurry consumption, as well as investing in technologies to minimize waste and emissions.

This trend reflects a broader industry shift toward sustainability, as companies recognize the importance of reducing their environmental footprint while maintaining high standards of performance and efficiency in semiconductor manufacturing.

Segmentation Analysis

The global market is segmented based on type, application, and geography.

By Type

Based on type, the market is categorized into equipment and consumables. The equipment segment led the chemical mechanical planarization market in 2023, reaching a valuation of USD 3,953.0 million. The equipment segment is further subdivided into polishing and grinding and slurry testing. The continuous advancements in semiconductor technology require highly sophisticated CMP equipment to achieve the precise surface planarization needed for modern electronic devices.

Increasing investments in semiconductor manufacturing facilities, particularly in the Asia-Pacific region, are boosting demand for advanced CMP equipment. Additionally, the ongoing miniaturization of electronic components necessitates more refined and accurate CMP tools. The growth of the equipment segment is further supported by the pressing need for improved efficiency, higher yield rates, and reduced defect levels in semiconductor production processes.

By Application

Based on application, the chemical mechanical planarization market is classified into compound semiconductors, integrated circuits, MEMS and NEMS, and others. The integrated circuits segment is poised to witness significant growth at a CAGR of 7.27% through the forecast period (2024-2031). This growth is attributed to the rising demand for ICs in various applications, including consumer electronics, automotive, and telecommunications. The increasing complexity and miniaturization of ICs require advanced CMP processes to ensure high precision and performance.

The proliferation of technologies such as 5G, artificial intelligence, and the Internet of Things (IoT) is leading to increased demand for more sophisticated ICs. Additionally, investments in research and development for next-generation ICs are propelling the need for efficient and reliable CMP solutions, thus fostering the expansion of the segment.

Chemical Mechanical Planarization Market Regional Analysis

Based on region, the global market is classified into North America, Europe, Asia Pacific, MEA, and Latin America.

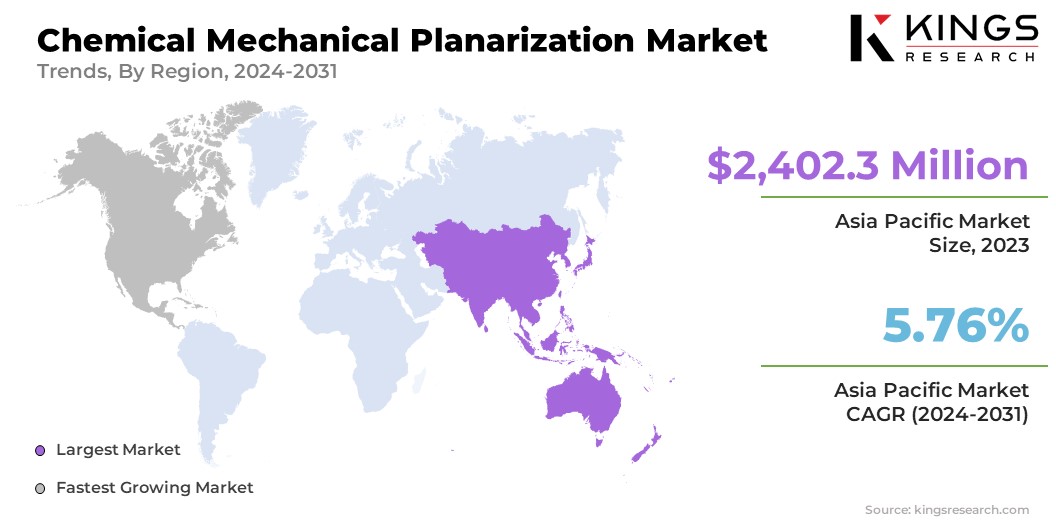

The Asia-Pacific chemical mechanical planarization market accounted for a share of around 38.56% in 2023, with a valuation of USD 2,402.3 million. This dominance is fueled by the region's robust semiconductor manufacturing industry, particularly in countries such as China, Taiwan, South Korea, and Japan. These nations are home to leading semiconductor manufacturers and maintain substantial investments in advanced manufacturing facilities.

Additionally, the presence of a well-established electronics industry and the increasing adoption of cutting-edge technologies are boosting the demand for CMP processes. Government initiatives and favorable policies supporting the semiconductor sector further contribute significantly to regional market expansion.

North America is set to grow at a robust CAGR of 7.51% over the forecast period. This rapid growth is reinforced by the region's strong focus on technological innovation and advancements in semiconductor manufacturing. The United States, in particular, is investing heavily in research and development for next-generation semiconductor technologies.

The growing demand for high-performance computing, artificial intelligence, and 5G technologies is propelling the need for advanced CMP processes. Additionally, the presence of major semiconductor companies and increasing investments in new manufacturing facilities are fueling the North America chemical mechanical planarization market expansion.

- The U.S. Department of Commerce initiated an updated Semiconductor Alert Mechanism, overseen by the International Trade Administration. This initiative aimed to identify and evaluate bottlenecks in semiconductor supply chains, facilitating better resource coordination to mitigate risks. Companies and stakeholders were urged to report any disruptions affecting global semiconductor manufacturing facilities and supply chains. This information aided in assessing potential disruptions, engaging with trade partners, and safeguarding the global semiconductor supply chain.

Competitive Landscape

The chemical mechanical planarization market report will provide valuable insight with an emphasis on the fragmented nature of the industry. Prominent players are focusing on several key business strategies such as partnerships, mergers and acquisitions, product innovations, and joint ventures to expand their product portfolio and increase their market shares across different regions.

Manufacturers are adopting a range of strategic initiatives, including investments in R&D activities, the establishment of new manufacturing facilities, and supply chain optimization, to strengthen their market standing.

List of Key Companies in Chemical Mechanical Planarization Market

- Air Products Inc.

- Applied Materials, Inc.

- Cabot Corporation

- EBARA Technologies, Inc.

- Fujimi Corporation

- Hitachi Chemical Co., Ltd.

- Lapmaster Wolters GmbH

- Okamoto Machine Tool Works,Ltd.

- The Dow Chemical Company

- LAM RESEARCH CORPORATION

The global chemical mechanical planarization market is segmented as:

By Type

- Equipment

- Polishing and Grinding

- Slurry Testing

- Consumables

- Slurry

- PAD

- PAD Conditioner

- Other Consumable Types

By Application

- Compound Semiconductors

- Integrated Circuits

- MEMS and NEMS

- Others

By Region

- North America

- U.S.

- Canada

- Mexico

- Europe

- France

- U.K.

- Spain

- Germany

- Italy

- Russia

- Rest of Europe

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia-Pacific

- Middle East & Africa

- GCC

- North Africa

- South Africa

- Rest of Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America

CHOOSE LICENCE TYPE

Frequently Asked Questions (FAQ's)

Get the latest!

Get actionable strategies to empower your business and market domination

- Deliver Revenue Impact

- Demand Supply Patterns

- Market Estimation

- Real-Time Insights

- Market Intelligence

- Lucrative Growth Opportunities

- Micro & Macro Economic Factors

- Futuristic Market Solutions

- Revenue-Driven Results

- Innovative Thought Leadership