Ethylidene Norbornene Market

Ethylidene Norbornene Market Size, Share, Growth & Industry Analysis, By Application (EPDM Rubber, Polymer and Chemical Intermediate, and Others), By End-Use Industry (Automotive, Construction, Consumer Goods, Flavor and Fragrance, and Others), and Regional Analysis, 2024-2031

Pages : 120

Base Year : 2023

Release : July 2024

Report ID: KR859

Ethylidene Norbornene Market Size

The global Ethylidene Norbornene Market size was valued at USD 1,052.2 million in 2023 and is projected to grow from USD 1,103.6 million in 2024 to USD 1,611.3 million by 2031, exhibiting a CAGR of 5.56% during the forecast period. The market is characterized by the growing demand driven by its rising use as a co-monomer in high-performance elastomers and in renewable energy applications such as wind turbines and solar panels.

Innovations in bio-based derivatives and sustainable practices are influencing its development in response to increasing regulatory and consumer preferences for environmental sustainability. In the scope of work, the report includes solutions offered by companies such as INEOS Oxide, Dow Chemical, Ningbo Titan Unichem Co. Ltd, Molbase, Devtaar GmbH, Merck KGaA, CHEMOS Gmbh & Co. KG, Exxon Mobil Corporation, Dayang Chem (Hangzhou) Co., Ltd and others.

The ethylidene norbornene market is experiencing steady growth, propelled by its essential role as a co-monomer in high-performance elastomers used extensively in automotive, construction, and industrial applications. Additionally, ENB's exceptional weather resistance and durability make it indispensable in renewable energy sectors, particularly in wind turbine blades and solar panel encapsulation.

The market is evolving with the increasing adoption of bio-based ENB derivatives and sustainable manufacturing practices, largely attributable to stringent environmental regulations and surging consumer preferences for eco-friendly products. This dynamic landscape underscores ENB's pivotal role in supporting technological advancements and addressing global sustainability goals across diverse industries.

Ethylidene norbornene (ENB) is a bicyclic organic compound. It enhances the flexibility, durability, and resistance of elastomers to heat and chemicals, thereby playing an essential role in industries such as automotive, construction, and renewable energy. ENB's excellent weather resistance further makes it valuable in applications such as coatings for wind turbines and encapsulation materials for solar panels. Its versatility and performance characteristics contribute significantly to various technological advancements and the sustainable development of industrial products.

Analyst’s Review

The ethylidene norbornene market is poised to experience robust growth, mainly fueled by its critical role in enhancing the performance and durability of elastomers across diverse industries. This growth is further propelled by several key strategies such as the expansion of synthetic rubber production, especially for high-performance tires and automotive components, which is boosting the demand for ethylidene norbornene as a crucial co-monomer in EPDM rubber.

Innovation in polymer manufacturing enhances product characteristics such as heat resistance and elasticity, thereby benefiting sectors including automotive, construction, and consumer goods. Strategic partnerships and collaborations are enhancing R&D efforts while expanding market reach. Additionally, regulatory pressures for sustainability are leading to the widespread adoption of greener production methods, aligning ethylidene norbornene with trends toward recyclable and durable materials.

Ethylidene Norbornene Market Growth Factors

The automotive sector is experiencing a notable growth trajectory, mainly due to the increasing demand for high-performance elastomers and polymers. Ethylidene norbornene (ENB) plays a crucial role in this expansion, particularly as a co-monomer in the production of elastomers used in tires and seals.

ENB enhances the durability, flexibility, and resistance to heat and chemicals of these materials, making it essential for meeting stringent performance requirements in modern vehicles. As automotive manufacturers strive to improve fuel efficiency, safety, and longevity of vehicles, the demand for ENB-based elastomers continues to rise, highlighting its pivotal role in the evolving automotive industry landscape.

The volatility of raw material prices, particularly those of petrochemical derivatives used in its production, is expected to impede market growth. Fluctuations in prices may lead to increased production costs and margin pressures for manufacturers, thereby impacting profitability and pricing strategies. However, key players in the ethylidene norbornene market are navigating challenges through strategic approaches aimed at ensuring market competitiveness and sustainability.

They are investing significantly in research and development to innovate new ENB-based products and applications, thereby enhancing their technological capabilities and meeting evolving customer demands.

Ethylidene Norbornene Market Trends

The rise in renewable energy projects, notably wind turbines and solar panels, is spurring demand for materials such as ethylidene norbornene, known for its exceptional weather resistance and durability. ENB is crucial in wind turbine blades and solar panel encapsulation due to its ability to withstand extreme temperatures, UV radiation, and moisture.

- According to the IEA, wind energy holds significant potential for boosting renewable capacity growth, with solar PV and wind additions expected to more than double by 2028 compared to 2022. This expansion is set to continuously break records over the forecast period, aiming to reach nearly 710 GW.

This enhances the longevity and performance of renewable energy systems, ensuring operational reliability in challenging environments. As global initiatives prioritize sustainability, ENB's role in protecting and enhancing the efficiency of renewable energy infrastructure continues to grow, driving its adoption as a preferred material in these critical applications.

There is a growing trend toward adopting bio-based derivatives of ethylidene norbornene and implementing sustainable manufacturing practices within the chemical industry. This shift is fueled by stringent environmental regulations and increasing consumer preference for eco-friendly products. Bio-based ENB derivatives offer a renewable alternative to traditional petroleum-based sources, thereby reducing carbon footprint and lessening dependency on fossil fuels.

Manufacturers are investing heavily in research and development to innovate sustainable production methods that minimize environmental impact. By adopting these practices, companies are complying with regulatory requirements while catering to a rising demand for greener solutions, thereby contributing to environmental sustainability goals.

Segmentation Analysis

The global market is segmented based on application, end-use industry, and geography.

By Application

Based on application, the ethylidene norbornene market is categorized into EPDM rubber, polymer and chemical intermediate, and others. The EPDM rubber segment garnered the highest revenue of USD 609.1 million in 2023. EPDM (Ethylene Propylene Diene Monomer) rubber is a highly versatile elastomer utilized extensively in the automotive, construction, electrical, and consumer goods sectors. Its superior attributes, including heat resistance, durability, and UV stability, make it suitable for diverse applications such as automotive seals, roofing membranes, and electrical insulation.

This progress is further bolstered by sustained demand from automotive manufacturing, infrastructure development, and renewable energy projects globally. Ongoing advancements in polymer chemistry and sustainable manufacturing practices further enhance EPDM's appeal, which is likely to foster segmental growth.

By End-Use Industry

Based on end-use industry, the ethylidene norbornene market is categorized into automotive, construction industries, consumer goods, flavor and fragrance, and others. The automotive segment is foreseen to garner the highest revenue of USD 679.9 million by 2031. The automotive sector is experiencing significant transformation as a result of technological advancements and evolving consumer preferences.

It encompasses a broad spectrum of products, from essential components such as EPDM rubber for seals and gaskets to cutting-edge materials and electronics used in electric vehicles (EVs) and autonomous driving systems. These factors are expected to augment the growth of the segment in the near future.

Ethylidene Norbornene Market Regional Analysis

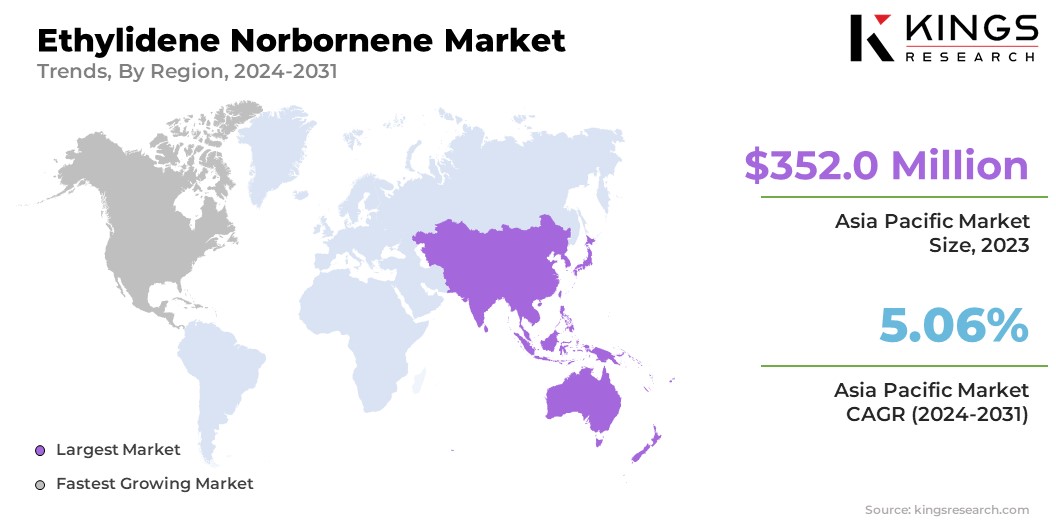

Based on region, the global market is classified into North America, Europe, Asia-Pacific, MEA, and Latin America.

The Asia-Pacific ethylidene norbornene market share stood around 33.45% in 2023 in the global market, with a valuation of USD 352.0 million. This notable expansion is attributed to robust industrialization and expanding automotive and construction sectors. Countries such as China, Japan, South Korea, and India are at the forefront of this considerable growth.

The automotive industry's demand for ENB in manufacturing high-performance elastomers for seals, gaskets, and hoses is substantial. This demand is bolstered by the region's robust automotive production and export activities in the region. Additionally, rapid infrastructure development and increasing construction activities propel the demand for ENB in applications such as roofing membranes and waterproofing solutions.

North America is poised to experience substantial growth at a CAGR of 6.55% over the forecast period, primarily due to advanced technological capabilities and stringent regulatory standards. The region's robust automotive sector heavily relies on ENB, utilizing it extensively in the production of high-performance elastomers for automotive seals, gaskets, and hoses.

Innovations in electric vehicle (EV) technologies and lightweight materials further bolster the demand for ENB. Additionally, North America leads in sustainable practices, with a major focus on reducing environmental impact through eco-friendly ENB derivatives and green manufacturing initiatives. This proactive approach ensures North America's prominence in driving innovation and meeting evolving demands in the ENB sector.

Competitive Landscape

The ethylidene norbornene market report will provide valuable insight with an emphasis on the fragmented nature of the industry. Prominent players are focusing on several key business strategies such as partnerships, mergers and acquisitions, product innovations, and joint ventures to expand their product portfolio and increase their market shares across different regions.

Companies are implementing impactful strategic initiatives, such as expanding services, investing in research and development (R&D), establishing new service delivery centers, and optimizing their service delivery processes, which are likely to create new opportunities for market growth.

List of Key Companies in Ethylidene Norbornene Market

- INEOS Oxide

- Dow Chemical

- Ningbo Titan Unichem Co. Ltd

- MOLBASE

- Devtaar GmbH

- Merck KGaA

- CHEMOS GmbH & Co. KG

- Exxon Mobil Corporation

- DAYANG CHEM (HANGZHOU) CO., LTD

The global ethylidene norbornene market is segmented as:

By Application

- EPDM Rubber

- Polymer and Chemical Intermediate

- Others

By End-Use Industry

- Automotive

- Construction

- Consumer Goods

- Flavor and Fragrance

- Others

By Region

- North America

- U.S.

- Canada

- Mexico

- Europe

- France

- U.K.

- Spain

- Germany

- Italy

- Russia

- Rest of Europe

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia-Pacific

- Middle East & Africa

- GCC

- North Africa

- South Africa

- Rest of Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America

CHOOSE LICENCE TYPE

Frequently Asked Questions (FAQ's)

Get the latest!

Get actionable strategies to empower your business and market domination

- Deliver Revenue Impact

- Demand Supply Patterns

- Market Estimation

- Real-Time Insights

- Market Intelligence

- Lucrative Growth Opportunities

- Micro & Macro Economic Factors

- Futuristic Market Solutions

- Revenue-Driven Results

- Innovative Thought Leadership